Predicting Droplet Size in Sprays

Spraying a cleaning product on a kitchen counter may be a mundane task, but it embodies a wide-reaching environmental problem. In atomized sprays like these, the largest droplets land on the surface as desired, while the smallest ones drift away and evaporate, wasting liquid and contaminating the surroundings. As Isaac Jackiw of the University of Alberta, Canada, says, “If you have an intuitive understanding of where the different sizes come from, then you can start to imagine specific targeted approaches for preventing unwanted sizes.” He and his colleagues have now developed a physics-based model that predicts the distribution of droplet size in sprays emitted from a nozzle. Jackiw presented the work at the Canadian Chemical Engineering Conference in Toronto this month.

In classical models of aerodynamic droplet breakup, airflow hits a liquid and causes it to explode into droplets. To explain the average droplet size, theorists have often focused on a single, dominant mechanism. But these methods have not been able to directly predict the distribution in droplet sizes, Jackiw says. His approach can estimate the size distribution by incorporating several different mechanisms, each of which contributes droplets in a particular size range.

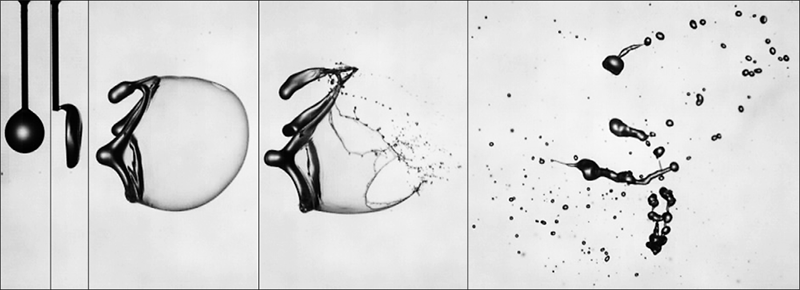

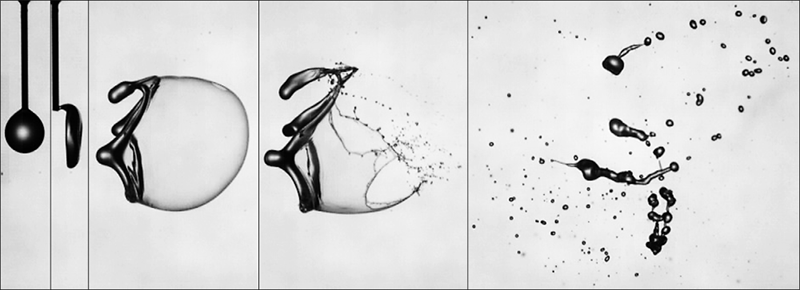

The model starts with a spherical droplet, which could be part of a liquid stream coming out of a nozzle. The droplet impacts with the surrounding air, causing its front face to flatten into a pancake shape. Jackiw’s team previously described how this flattened droplet deforms into a balloon-like “bag” structure, with a thick “rim” containing material from the pancake’s periphery. Eventually, the bag and rim components fragment via several mechanisms that lead to a plethora of different droplet sizes (Fig. 1). Which mechanism dominates—rim breakup, bag breakup, or nodes that form when a popped bag collides with the rim—depends on the balance between the airflow and the restoring surface tension of the droplet. Each mechanism, in turn, gives rise to a different characteristic distribution of fragmented droplet sizes.

To apply these observations to practical spray conditions, Jackiw and his colleagues designed experiments using a small commercially available nozzle. Water was pumped through the nozzle, forming a sinuous liquid jet. A high-speed camera captured the breakup of this jet, allowing the researchers to measure the size of the resulting fragments under various flow conditions. They then compared these data to their model’s predictions and showed that the two matched. In particular, the model could predict the distribution of droplet size at different distances from the nozzle.

In the real world, however, spray liquids are more complex than water. Agricultural pesticide sprays, for example, are often thickened with solid particles, such as viscous polymers. These additives increase the viscosity and slow the deformation, which leads to larger droplets that are less likely to carry pesticide beyond the target fields. But the exact mechanism behind this droplet enlargement is not known, Jackiw says. To explore the effect of additives, he and his colleagues have used a syringe to place glycerine solution droplets in the path of an air stream. So far, these studies have shown that the critical point at which droplet breakup begins is delayed for more viscous fluids—but the researchers have yet to determine the specific pathways that lead to different sizes.

Besides viscosity, Jackiw is looking at other inputs—such as nozzle type and flow rate—that might control droplet size. This effort might eventually lead to a new nozzle or bottle design that mechanically suppresses small droplets without the need of additives. Such a development could help improve home cleaning spray products by reducing the risk of users inhaling unhealthy chemicals transported into the air by small droplets, Jackiw says.

Sergei Sazhin, a physicist who specializes in fluid and thermal physics at the University of Brighton, UK, agrees that predicting the size distribution of sprays is an important and widely studied problem. He says that Jackiw’s work does a “very good job of opening a new direction in the research of spray formation.” He expects that further development and refining of the model will improve the matching between model predictions and experimental data—and that the approach can be generalized to other atomizers and liquids.

–Rachel Berkowitz

Rachel Berkowitz is a Corresponding Editor for Physics Magazine based in Vancouver, Canada.